As electric vehicles (EVs) continue to gain popularity, the demand for efficient and reliable charging infrastructure has grown significantly. DC charging stations play a crucial role in facilitating rapid charging for EVs, offering faster charging times compared to traditional AC charging stations. However, not all DC charging stations are created equal. In this article, we'll explore the differences between Injet New Energy Integrated DC Charging Stations and traditional DC charging stations.

Injet New Energy Integrated DC Charging Station:

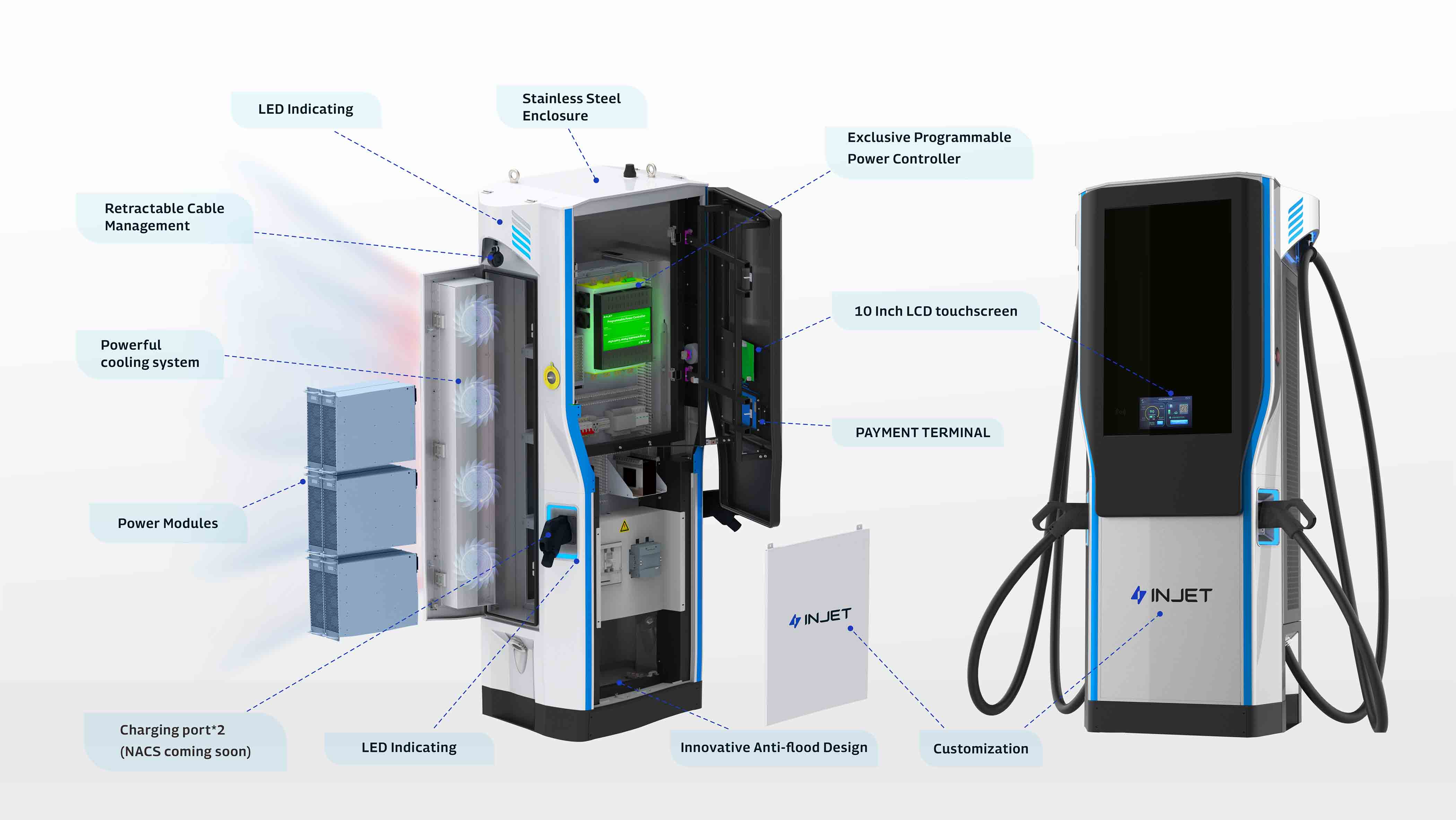

The Injet New Energy Integrated DC Charging Station sets itself apart with its innovative features and components, including:

Programmable Power Controller: Exclusive to INJET, the programmable power controller allows for precise control and optimization of power delivery to the charging module, ensuring efficient charging while minimizing energy wastage.

Integrated Smart HMI: The integrated smart Human-Machine Interface (HMI) provides a user-friendly interface for both operators and EV owners, allowing for seamless interaction and monitoring of the charging process.

Charging Module: The charging module delivers high-speed DC charging to EVs, enabling rapid replenishment of battery power.

Cabinet: The cabinet houses the various components of the charging station, providing protection from environmental factors and ensuring durability.

Cable & Plug: High-quality cables and plugs are provided for convenient and reliable connection between the charging station and EV.

(Injet New Energy Integrated DC Charging Station-Ampax)

Maintenance of the Injet New Energy Integrated DC Charging Station is streamlined and efficient, with the integrated power controller playing a crucial role:

Integrated Controller Maintenance: Maintenance of the integrated controller typically requires less than 8 hours, with quick diagnosis of faults and easy replacement of components.

Rapid Fault Resolution: In the event of a failure, the background system can quickly identify the fault, allowing for swift resolution within 2-4 hours.

Minimal Downtime: With the ability to directly replace the power controller, downtime is minimized, ensuring continuous operation of the charging station.

Traditional DC Charging Station:

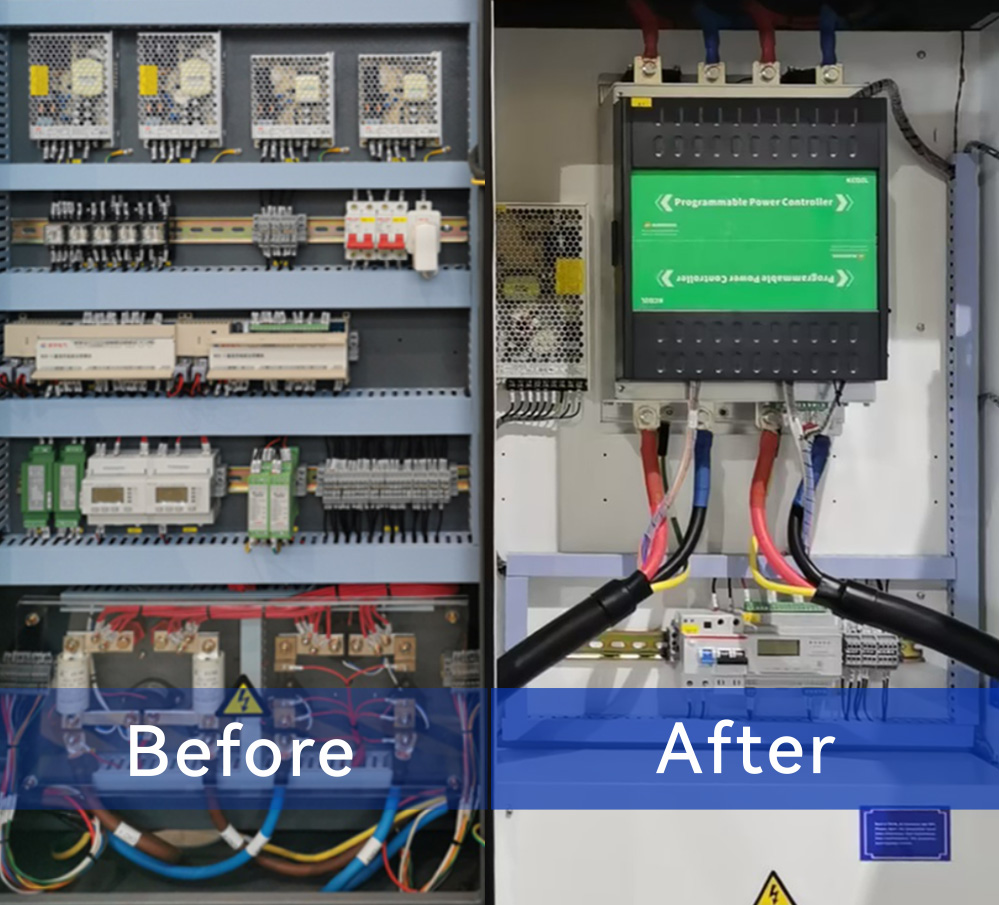

In contrast, traditional DC charging stations feature a different set of components and maintenance procedures:

DC Watt-Hour Meter

Voltage Detection Transmitter

Insulation Detector

Charging Pile Controller

AC/DC Power Supply

Additional Components: Including MCB, Relay, SPD, MCCB, AC Contactor, DC Vacuum Contactor, terminal blocks, and wires.

(Without Programmable Power Controller & With Programmable Power Controller)

Maintenance of traditional DC charging stations typically involves longer downtime and more complex procedures:

Lengthy Repair Process: Repairing traditional DC charging stations can take anywhere from 2 to 10 days, depending on the nature of the fault and availability of spare parts.

Diagnosis and Repair: Maintenance personnel must first visit the site to diagnose the fault, followed by the procurement and replacement of necessary components.

Extended Downtime: With multiple components and potential points of failure, traditional DC charging stations may experience extended downtime during maintenance and repair.

INJET Integrated DC Charging Stations offer a superior charging experience compared to traditional DC charging stations, with advanced features, streamlined maintenance, and minimal downtime. Reduce maintenance costs and repair time. As the demand for EV charging infrastructure continues to grow, innovative solutions like the INJET Integrated DC Charging Station will play a crucial role in shaping the future of electric mobility.

Post time: Mar-05-2024